Popular Design for Melamine Powder Manufacture - Leading Manufacturer for China Melamine Formaldehyde Resin Molding Compound Melamine Moulding Powder for Making Kitchenware – Huafu

Popular Design for Melamine Powder Manufacture - Leading Manufacturer for China Melamine Formaldehyde Resin Molding Compound Melamine Moulding Powder for Making Kitchenware – Huafu Detail:

Our firm aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for Leading Manufacturer for China Melamine Formaldehyde Resin Molding Compound Melamine Moulding Powder for Making Kitchenware, We sincerely do our best to provide the most beneficial assistance for many of the shoppers and businessmen.

Our firm aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for China Melamine Moulding Powder, Melamine Powder, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which are going to be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

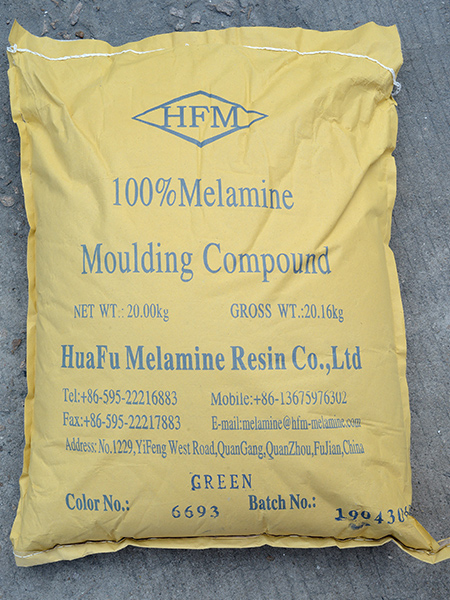

Melamine Formaldehyde Resin Powder is made from melamine formaldehyde resin and alpha-cellulose. This is a thermosetting compound that is offered in various colors. This compound has outstanding characteristics of molded articles, wherein resistance against chemical and heat are excellent. Furthermore, hardness, hygiene and surface durability are also very good. It is available in pure melamine powder and granular forms, and also the customized colors of melamine powder required by customers.

Physical Property:

Melamine moulding compound in powder form are based on melamine-formaldehyde resins fortified with high-class celluloses reinforcement and further modified with minor amounts of special purpose additives, pigments, cure regulators and lubricants.

Advantages:

1.It has a good surface hardness, gloss, insulation, heat resistance and water resistance

2.With bright color, odorless, tasteless, self-extinguishing, anti-mold, anti-arc track

3.It is qualitative light, not easily broken, easy decontamination and specifically approved for food contact

Applications:

1.Kitchenware / dinnerware

2.Fine and heavy tableware

3.Electrical fittings and wiring devices

4.Kitchen utensil handles

5.Serving trays, buttons and Ashtrays

Storage:

Keep containers airtight and in a dry and well-ventilated place

Stay away from heat, sparks, flames and other sources of fire

Keep it locked and stored out of reach of children

Stay away from food, drinks and animal feed

Store according to local regulations

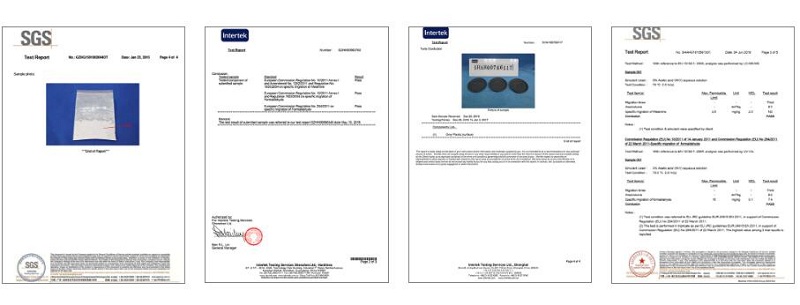

Certificates:

SGS and Intertek passed melamine moulding compound, click the picture for more detail information.

Factory Tour:

Products and Packaging:

Product detail pictures:

Related Product Guide:

Is Melamine Safe? From the FDA

Synthesis of Nitrogen-doped Graphene | Melamine Glaze Powder

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for Popular Design for Melamine Powder Manufacture - Leading Manufacturer for China Melamine Formaldehyde Resin Molding Compound Melamine Moulding Powder for Making Kitchenware – Huafu, The product will supply to all over the world, such as: Kazakhstan, Peru, Swedish, We have a excellent team supplying professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our products.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.