2017 High quality Melamine Powder 99.8% For Resin - Trending Products China Glazing Powder Used in A5 Melamine Molding Powder (MF) Products Finish Processes – Huafu

2017 High quality Melamine Powder 99.8% For Resin - Trending Products China Glazing Powder Used in A5 Melamine Molding Powder (MF) Products Finish Processes – Huafu Detail:

We've been committed to offering easy,time-saving and money-saving one-stop purchasing support of consumer for Trending Products China Glazing Powder Used in A5 Melamine Molding Powder (MF) Products Finish Processes, Our remaining objective is "To attempt the best, To generally be the Best". You should sense free of charge to call with us when you have any prerequisites.

We've been committed to offering easy,time-saving and money-saving one-stop purchasing support of consumer for China Melamine Glazing Powder, LG110 LG220 LG250, If you give us a list of products you are interested in, along with makes and models, we can send you quotations. Please email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

Melamine Glazing Powder has the same origin as melamine formaldehyde moulding compound. It is also the material of the chemical reaction of formaldehyde and melamine.

Actually, Glazing Powder is used to put on surface of the tableware or on the decal paper to make tableware shinning. When used on tableware surface or decal paper surface, it can increase the degree of surface brightening, makes the dishes more beautiful and generous.

Glazing Powders have:

1.LG220: shinning powder for the melamine tableware products

2.LG240: shinning powder for the melamine tableware products

3.LG110: shinning powder for the urea tableware products

4.LG2501: glossy powder for foil papers

HuaFu has the best products of the Crown of Quality in the local industry.

Physical Property:

Glazing Powder: non-toxic, tasteless, odorless, is ideal amino molding plastic material after-Clear, with light to make the product wear. The article coated with melamine resin powder, glazing powder has a shinny and harder surface and resists better to cigarette burns, foodstuffs, abrasion and detergents.

Advantages:

1.It has a good surface hardness, gloss, insulation, heat resistance and water resistance

2.With bright color, odorless, tasteless, self-extinguishing, anti-mold, anti-arc track

3.It is qualitative light, not easily broken, easy decontamination and specifically approved for food contact

Applications:

1.Kitchenware / dinnerware

2.Fine and heavy tableware

3.Electrical fittings and wiring devices

4.Kitchen utensil handles

5.Serving trays, buttons and Ashtrays

Storage:

Keep containers airtight and in a dry and well-ventilated place

Stay away from heat, sparks, flames and other sources of fire

Keep it locked and stored out of reach of children

Stay away from food, drinks and animal feed

Store according to local regulations

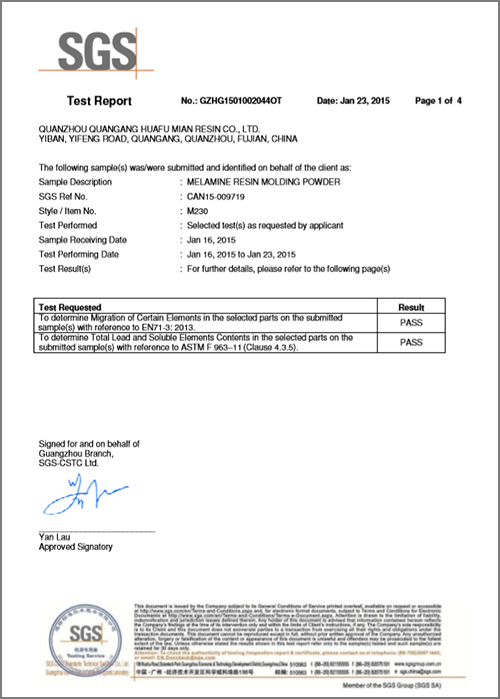

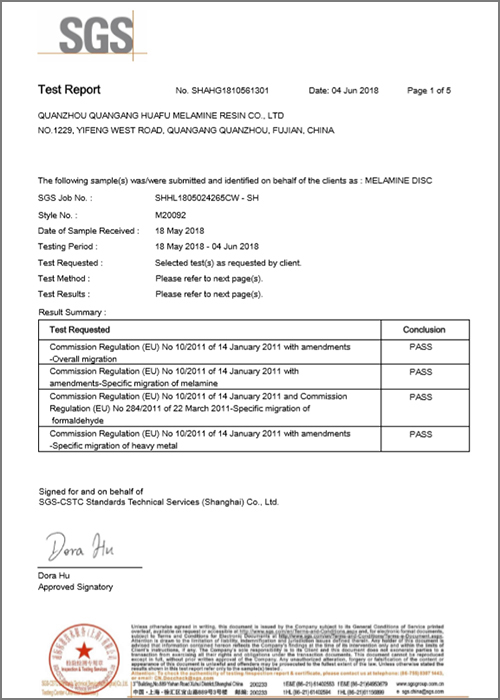

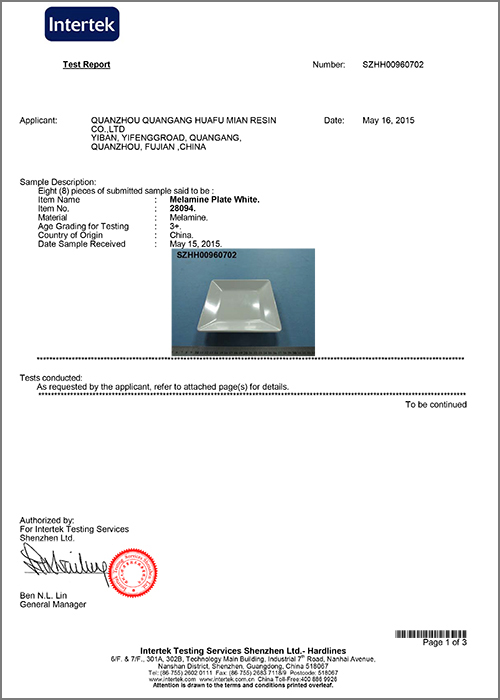

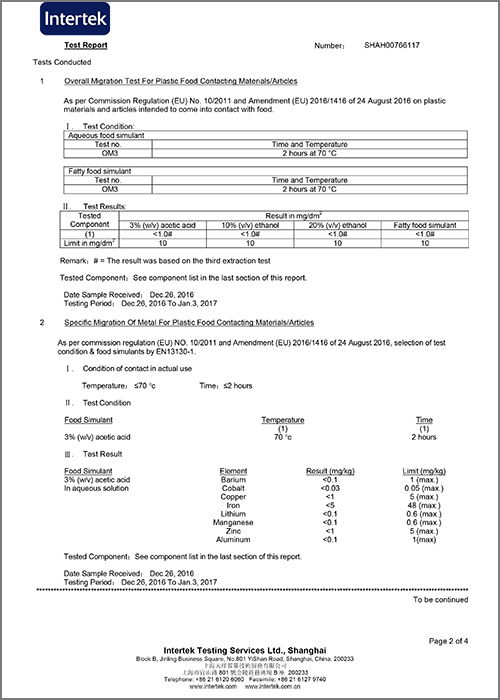

Certificates:

Factory Tour:

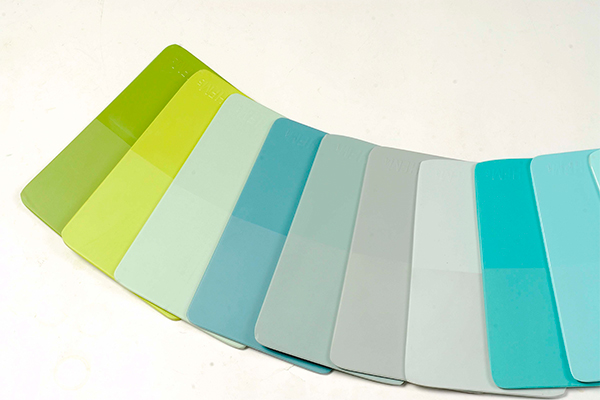

Product detail pictures:

Related Product Guide:

The Global Melamine Formaldehyde Market | Melamine Powder 99.9%

Melamine Powder Market Report Enhancement By 2027 With Latest Technology & Future Scope

We stick with the theory of "quality first, company first, steady improvement and innovation to satisfy the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for 2017 High quality Melamine Powder 99.8% For Resin - Trending Products China Glazing Powder Used in A5 Melamine Molding Powder (MF) Products Finish Processes – Huafu, The product will supply to all over the world, such as: Kazakhstan, Slovakia, Istanbul, We provide good quality but unbeatable low price and the best service. Welcome to post your samples and color ring to us .We will produce the goods according to your request. If you are interested in any products we offer, please feel free to contact us directly by mail, fax, telephone or internet. We are here to answer your questions from Monday to Saturday and looking forward to cooperating with you.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.